The adhesive on the back side of the Aspect tiles is highly aggressive and pressure sensitive. Proper wall preparation is required. Aspect can be installed over most structurally sound substrates if they are clean, flat, smooth, dry and free of dust, wax, soap scum and grease. Acceptable substrates are drywall, plaster or clean, smooth tile (glazed, porcelain-type tile; not porous or textured). Any damaged, loose or uneven areas must be repaired, patched, leveled and primed. Fill cracks and irregularities with wallboard compound or spackling, then sand smooth with fine-grit sandpaper. Also, to prevent the color of your wall from showing through the seams of your Glass Aspect installation, one coat of paint (in the finish of your tiles) can be applied to your wall before installation.

With peel and stick installation, grout is not needed between tiles. Even with careful layout and installation, gaps may appear between the tiles. Accordingly, we recommend that you paint the wall area a color that matches your tile color. This will hide any small gaps if they happen to appear.

Yes. To ensure years of enjoyment of your Aspect installation, and for installations near sinks or tubs, the substrate to which Aspect is applied must be primed with an oil-based primer to seal it – ensuring a stable substrate. Aspect is impervious to water but substrates such as drywall or plywood are not.

No, the adhesive is not engineered to be used in a wet environment such as a shower.

First, be sure to follow the instructions for substrate preparation. After you have the tile aligned where you want it, firmly press the tile over its entire surface area to be sure it adheres properly. You can test the adhesion by pulling slightly on the tile. It should be securely attached. If not, it might be necessary to add additional adhesive. Use a high-quality construction adhesive. Be sure to allow the adhesive 24 hours to set-up. See below for additional information. Our recommended adhesives are Loctite® PL Premium®, Loctite® PL Premium Advanced®, LePage® PL Premium® (Canada). Carefully read and follow manufacturer’s directions for the adhesive.

Occasionally, even after properly preparing the substrate, the surface can still have bows, high spots, ridges or uneven areas. One way to test the area of the substrate to which the tile is to be applied is to place a tile (with the back liner unpeeled) on the area to see if it “rocks” or if it has a solid, flat foundation. If proper adhesion is difficult or impossible, a tube adhesive can be applied to the back of the tile to allow good adhesion. Be sure to remove the release film on the back of each tile before applying additional adhesive. Apply no more than about five pea-sized dots of adhesive to the back of a full tile. Keep the adhesive a half-inch from the edges. Press the tiles into place. If adhesive squeezes out around the tiles, be sure to wipe it off before it dries.

Use 100% polyurethane (tube) adhesive, such as Loctite® PL Premium®, Loctite® PL Premium Advanced®, LePage® PL Premium® (Canada). Carefully read and follow manufacturer’s directions for the adhesive.

A tile can fall off as a result of improper substrate preparation such as a substrate that is not clean, flat, smooth, dry and free of dust, wax, soap scum and grease. Or, bumpy, wavy surfaces may cause tiles to fall off.

A sand-less grout can be used. A grout containing sand is not recommended as the grout may scratch the surface of the tile in the cleanup process. If you want a grout-line look, colored or white silicone caulking will have the same effect, is easier to apply and provides a water-tight seal. Be sure to remove excess caulk or grout before it dries.

No. Aspect Peel and Stick backsplash tiles are manufactured for indoor use only..

Aspect tiles can withstand heat up to 140°F without causing any damage to the product. We recommend a minimum 6-inch space between the heat source or burner and the installed tiles. You may also refer to your stove’s (or other heat source) manufacturer for specific information.

The adhesive will not be affect by temperatures of 150°F or less.

Select a cutting method for cutting glass according to the shape of the cut that you want to make. Straight cuts can be made with a scoring tool. Compound intricate cuts should be made with a glass-cutting wet saw or by a professional glass shop.

For straight cuts, use a glass scoring tool.

a) Measure and mark the tile with a marker on the top of the glass tile where the cut must be made. Run your finger along the surface of the glass where you plan to score before marking to remove any particles that could affect scoring.

b) Applying light oil (WD40™ or even cooking oil) to the scoring wheel will help achieve smoother scoring lines. Apply pressure to the glass as you pull the cutter along the surface, rolling on the scoring wheel. The score must run from one edge of the glass to the other edge.

c) When scoring, a gritty sound means that you are pushing too hard. A smooth, tearing sound is what you want. Score along a straight edge. Use a metal ruler or straightedge.

d) After scoring, the tiles can be broken on a table. Place a soft cloth or cardboard on the table to prevent damage. Place the tile, finished side up, with the score along the edge of a table then push the part to be cut downward. You can also just grip the glass firmly, one hand on either side of the score. Then use a snapping action with your wrists to break the glass.

e) Use fine sandpaper or emery cloth to smooth and debur sharp edges resulting from glass cutting. Be careful not to scratch the finished surface of the glass.

Follow all safety procedures, including using safety eyewear and protective gloves when using scoring tools and cutting glass. If compound or notched cuts, around an outlet for example, are required, you may need to use a wet glass-cutting saw, available for rent from most home centers. In many cases, cuts that you cannot make with a scoring tool can be easily done by a professional glass shop. Remember to mark your tiles for cutting first.

You can use soap, water and a soft cloth. A glass cleaner or grease cutter can also be used.

Aspect should be treated like any other tile. Clear or colored caulk is a good option. Caulk can be painted to match wall color if preferred. Wood, plastic or other types of trim also work well depending on your preference and abilities.

These applications are not recommended, as the rubbing could potentially scratch the surface of the tile.

Aspect tiles and panels will last well-beyond the lifetime of your kitchen, bath or wall project. The tiles and panels are virtually indestructible under normal use.

Not easily, but it can be scratched like any glass surface.

Working from the center out would balance the working area and ensure your largest tiles in the middle of your space. This could be important when a designer pattern is used. However, you can start at one end and work to the other.

Start by applying pressure slowly underneath the 3’’ side of a tile and increase pressure lifting the tile up. Note: Be careful not to damage the adjacent tile. A 1” putty knife or similar tool that applies even pressure across the surface upon which you are prying is recommended. Note: subsurface material like drywall may be affected due to the aggressive nature of the tile adhesive which may require touch up or priming prior to replacing the tile.

Yes, possibly. Caution is advised when removing tile to eliminate as much old adhesive as possible. Some repairs may be necessary if this happens.

Aspect tiles meet or exceed ASTM E84 Class 1 and Class A Surface Burn Characteristics.

No, matching outlet and plate covers for Glass Aspect are not available at this time. We recommend you visit www.wallplatewarehouse.com to find an outlet that you prefer.

You may see a warning on this product regarding California’s Proposition 65, the Safe Drinking Water and Toxic Enforcement Act of 1986. It is intended to help Californians make informed decisions about protecting themselves from chemicals known to cause cancer, birth defects or other reproductive harm. The Proposition requires the state to maintain and update a list of chemicals known to the state to cause cancer or reproductive toxicity.

Proposition 65 is designed to inform consumers. This is not the same as a regulatory decision that a product is “safe” or “unsafe”. Our products emit no volatile organic compounds (VOC’s) and are in no way harmful if the product is used for its intended purpose. At Acoustic Ceiling Products, customer satisfaction is our number one priority and we will be happy to provide any additional information, technical specs or data you may need on any of our products.

Painting is not recommended for glass tiles as the coating applied to the surface is a high durability material.

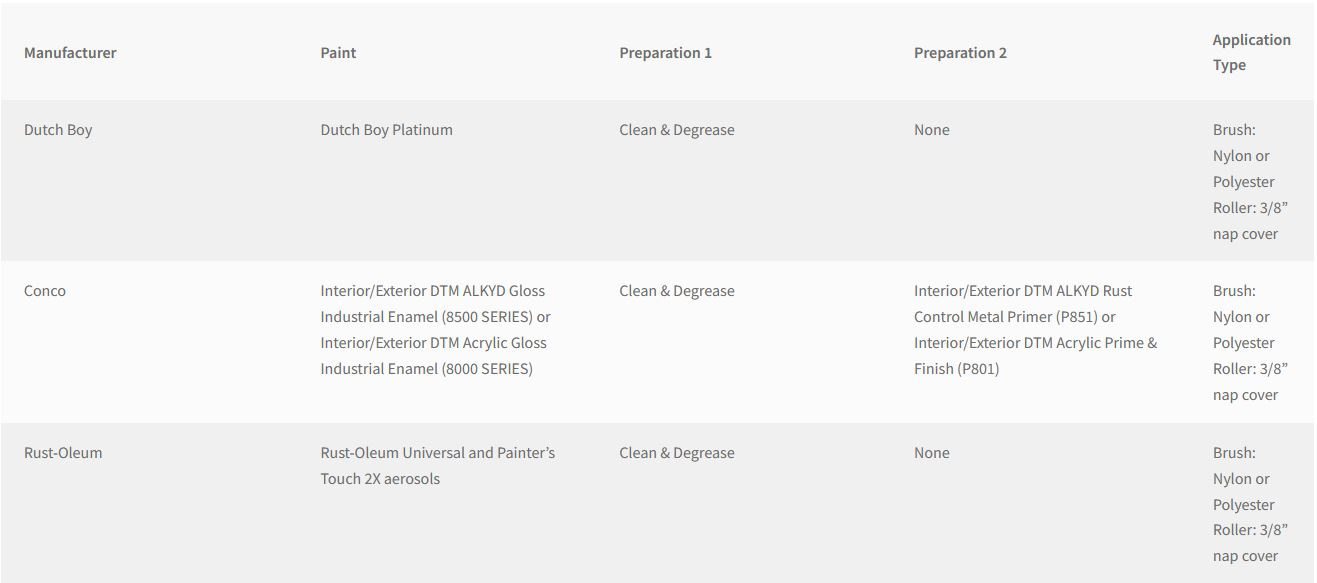

To paint Aspect metal tiles, the recommended paint and preparation steps are below. For proper adhesion, be sure to complete both preparation steps:

Yes, you can use on the interior of your camper and we recommend using method 2 of our installation guide which states to use supplemental adhesive due to road vibrations and temperature swings.